Description

Introduction

The success for designing high efficiency engines largely depends

on our ability to process materials that can withstand high temperatures

without failure. A tremendous amount of research has been devoted

to finding new Ni-based superalloys which are thermodynamically

and structurally stable at higher temperatures and for longer

periods of time. Ni-based superalloys consist of ordered intermetallic

g'(Ni3Al) precipitates embedded in a disordered face-centered

cubic (fcc) g matrix. The control of the g+ g' two-phase microstructure

and its high-temperature stability is the key to the success for

the development of superalloys with desired high temperature properties

since the g' precipitate volume fraction, precipitate morphology,

and distribution in these alloys strongly affect their mechanical

properties (e.g. strength, fatigue and creep). The precipitate

morphology and spatial distribution are known to depend on a number

of factors which include the precipitate volume fraction, alloy

compositions, temperature, lattice mismatch between the precipitates

and matrix, presence of dislocations, and applied stress loads.

In current laboratory and industrial practice, the traditional

trial-and-error method is still the major approach to optimizinge

the alloy chemistry and processing conditions for achieving desirable

desired microstructuresmechanical properties for of Ni-based superalloys.

This usually requires many long and expensive experimentations.

However, with the rapid development in computer technology and

recent advances in computational modeling, we believe it is now

possible to develop a set of physics-based, user-friendly computational

tools that can be employed for both fundamental materials research

and design of new advanced materials. The main objective of the

proposal is to develop a set of integrated and predictive computational

tools that can be employed to determine the relationships among

chemistry, microstructure and mechanical properties of single-crystal

superalloys at high temperatures ( > ).

Proposed approaches, the rationale, and new innovations

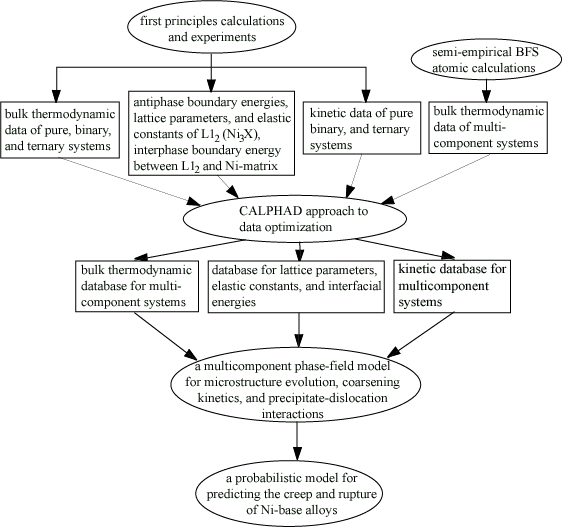

We proposed to build the set of computational tools based on the

following approaches (See Fig. 1): (ia) first-principles calculations

of the thermodynamic and kinetic parameters, lattice parameters,

and elastic constants for low-order systems including single-component

systems, binary and ternary alloys as well as thermodynamic properties

of point defects, dislocations and antiphase boundary energies

in such systems, and semi-empirical atomistic calculations of

thermodynamic properties of multicomponent systems using the BCS

(Bozzolo-Ferrante-Smith) method[1];, (iib) computational thermodynamicsCALPHAD

(often referred to as CALculation of PHAse Diagrams) approach[2]

for to constructing thermodynamic, kinetic and crystallographic

databases for multicomponent systems using the data obtained from

first-principles calculations, semi-empirical BCS method, and

experimental measurements in low-order systems (number of components

> 3) based on the thermodynamic and kinetic data obtained from

low order systems and for determining the phase-equilibria and

thermodynamics of multicomponent alloys; (iiic) a phase-field

method[3] for predicting the microstructure evolution and coarsening

kinetics of g' gamma-prime precipitates in multicomponent alloys

with the fundamental thermodynamic, kinetic and crystallographic

input directly from databases with input from the thermodynamic

and kinetics databases; and (ivd) a ?? creep property method ofmodel

for predicting and extrapolating approach for modeling the creep

and rupture properties of single-crystal Ni-based superalloys

with information obtained from the microstructure model, crystallographic

databases, and creep measurements using the microstructure information

obtained from phase-field simulations. For validating the computational

models, critical experiments on the determination of thermodynamic

data and high-temperature phase-equilibria will be conducted at

Penn State using the newly developed combinatorial approach. The

measurement of coarsening kinetics of g' gamma-prime precipitates

at high temperatures (> precipitates will also be performed

at Penn State in collaboration with the Advanced Metals Branch

of the Materials Division at NASA-GRC, and high-temperature creep

testing of single-crystal Ni-based superalloys will be conducted

at University of Florida. All the experimental validation will

be performed in close collaboration with the Advanced Metals Branch

of the Materials Division at NASA-GRC. In addition, Dr. Zhao at

General Electric, who pioneered the combinatorial approach for

structural materials[4, 5], has agreed to help and advise a graduate

student in carrying out part of the experimental validation of

thermodynamic/kinetic databases.

The rationales for proposing such a multiscale computational

approach are as follows. Recent advances in first-principles calculations

have made it possible to predict accurate thermodynamic properties,

such as formation energies and enthalpies, of pure and binary

alloys, ternary and multicomponent alloys using only the atomic

numbers as the input. However, up to now it is not computationally

tractable, for the foreseeable future, to use first-principles

calculations to accurately determine the configurational and vibrational

entropy contribution to the total free energy directly from first-principles

for a multicomponent system. Several studies have shown progress

recently in binary systems. rationalsOn the other hand, semi-empirical

methods based on the CALPHAD approach have been very successful

in determining the phase equilibria of multicomponent commercial

alloys, often with ten components or more[17, 18]. The CALPHAD

approach builds thermdynamicthermodynamic databases for multicomponent

systems using data obtained in single-component, binary and ternary

systems. Therefore, a marriage of first-principles calculations

of simple low-order systems and the CALPHAD approach will allow

one to develop thermodynamic databases for multicomponent systems

from first-principles. Since the CALPHAD approach uses extrapolation

of the data from experiments and first-principles calculations

of low-order systems to multicomponent systems, its accuracy for

multicomponent systems must be validated experimentally. To increase

the database reliability, we plan to utilize the expertise at

NASA on semi-empirical atomic calculations using the BFS method

to obtain additional thermodynamic data, in particular, the formation

enthalpies, of multicomponent systems in the database assessment.

A similar strategy can be adopted for developing kinetic databases

and databases for lattice parameters, elastic constants and interfacial

energies as a function of composition and temperature.

Fig. 1. An integrated set of computational tools

A recent important development in computational materials science

is the emergence of the powerful phase-field approach for modeling

phase transformations and microstructure evolution. It is based

on the fundamental thermodynamic and kinetic principles, but it,

which requires input data for the thermodynamic and kinetic parameters,

the lattice parameter and elastic constants dependence on composition

and order parameters. One of the main advantages of the field

approach is that the temporal evolution of any arbitrary microstructures

can be predicted without any a priori assumptions about their

evolution path. Precipitate disappearance and coalescence are

automatically taken into account, so there is no limit on the

volume fractions of precipitates that can be modeled. There is

no technical difficulty in extending from 2D to 3D simulations

except a significant increase in computational time and memory

requirements. We recently showed that even with current computer

technology, we were able to model realistic 3D systems with thousands

of g' precipitates in a g matrix at any given volume fractions[6].

On the other hand, using the traditional front-tracking models,

even the state-of-the-art boundary-integral method[7] is only

able to model the coarsening kinetics of precipitates at low volume

fractions; it cannot handle the topological changes during coalescence

of precipitates at high volume fractions, even in two dimensions

(2D), while the volume fractions of g' precipitates in most Ni-base

superalloys are typically about 50% or higher[8]. Using front-tracking

sharp-interface models, it is technically impossible to model

the evolution of more realistic 3D microstructures with high volume

fraction of precipitates, although modeling coarsening of small

volume fractions of spherical precipitates is possible. Moreover,

a traditional front-tracking model cannot distinguish the four

types of antiphase-related domains of g' precipitates that coexist

in a g+g' two-phase microstructure, which can have a significant

influence on the precipitate morphology and coarsening kinetics.

The difficulty of a sharp-interface description in treating the

topological changes during microstructure evolution is also the

main reason that the commercial code "DICTRA" can only be used

to model one-dimensional (1D) phase transformation and microstructure

problems. DICTRA is a general software package for simulation

of Diffusion Controlled TRAansformations in multicomponent systems

developed by the Royal Institute of Technology in Sweden. If the

proposed project is funded and successfully completed, a potentially

much more sophisticated computational tool than the current commercial

code "DICTRA" can be developed. Coupled with reliable thermodynamic

and kinetic databases, the proposed model can be used to predict

the coarsening kinetics of g' precipitates in multicomponent single-crystal

Ni-base superalloys with only the temperature and compositions

as the input, and therefore can be used in the design of superalloy

microstructures.

Our ultimate interest is to predict the mechanical properties

of an multicomponent alloy as a function of alloy chemistry, temperature

and time. Therefore, it is critical to link microstructures predicted

from phase-field simulations to the tensile and creep behavior

of Ni-based superalloys. For the tensile properties at relatively

low temperatures, the recent breakthrough advances in phase-modeling

of dislocation microstructures and dislocation slipping dynamics

makes it possible to study the effect of alloy chemistry, and

thus various solute species and the g' precipitate size, morphology,

and volume fraction on the stress-strain curve of Ni-base alloys.

However, for high temperatures at which multiple slip, cross-slip,

and dislocation climb are taking place, significant additional

effort is required to make the current phase-field technology

directly applicable to high-temperature creep. Moreover, in real

commercial superalloys, metallurgical defects (e.g., porosity,

inclusions, low-angle boundaries) due to processing are common.

To accurately predict the creep and the lifetime of an engine

component, the effect of these randomly created processing defects

on the creep properties must be incorporated in a creep model,

in addition to the effects of microstructural details (e.g., precipitate

size and morphology) which can be obtained from the microstructure

model. Therefore, one of the goals of the proposed research is

to develop a model that can predict the properties of Ni-base

superalloy single crystals that combines a probabilistic creep

property parameter. To develop such a model, extensive laboratory

testing of model and commercial alloys will be used to quantify

the effects of microstructural details, alloying additions and

metallurgical defects on the creep properties.

The proposed computational tools are highly innovative in the

following aspects. First of all, although the CALPHAD approach

has existed for more than two decades and has been extensively

used in calculating the phase equilibria in complex alloys, as

far as we are aware of, the proposed research presents the first

systematic effort to construct thermodynamic and kinetic databases

by using extensively first-principles and semi-empirical atomistic

calculations. Such an approach will allow one to build databases

which can be used to predict the phase equilibria in experimentally

unexplored compositional fields and for alloying species which

have not been studied experimentally. It will also improve the

reliability of databases by incorporating the thermodynamic data

of certain metastable or stable precipitates that are difficult

to isolate experimentally and whose structure and thermodynamic

properties are almost impossible to measure experimentally. Secondly,

the proposed research is the first attempt to build a database

for the lattice parameters (crystallographic), elastic constants,

and interfacial energies as a function of composition and temperature

for complex alloys. Third, preliminary phase-field models for

simple, elastically homogeneous binary Ni-base superalloys have

been developed at Penn State and other universities during the

last few years. The proposed effort in microstructure modeling

will be focused on developing an innovative computational microstructure

model for complex, elastically inhomogeneous, multicomponent systems

by incorporating recent advances at Penn State in developing fast

numerical algorithms for solving phase-field equations, capability

for modeling elastically inhomogeneous systems under applied stresses,

and a novel formulation for modeling precipitate microstructure

evolution in the presence of dislocations. Such an innovation

is critical for modeling the microstructure evolution in real

alloys in which the elastic constants are always inhomogeneous

and most likely multicomponent and in alloys under an applied

stress. Fourth, the proposed creation of an interface between

thermodynamic, kinetic, and crystallographic databases and the

phase-field model is a first major step to realize the potential

application of the phase-field model to practical alloy designs.

Finally, we proposed the first major effort to build a constitutive

creep model with input from a microstructure model while incorporating

the effect of processing defects such as porosity and low-angle

boundaries. The proposed probabilistic model will be a first of

its kind and it promises to improve significantly the accuracy

of existing extrapolation/interpolation model.

|